DRYMATIC II - Next Generation of time- and costeffective drying

The award winning DBK Drymatic System was developed to offer the Damage Management industry a cost-effective tool that would cater for a broad range of structural drying requirements including floor drying and moisture removal.

The award winning DBK Drymatic System was developed to offer the Damage Management industry a cost-effective tool that would cater for a broad range of structural drying requirements including floor drying and moisture removal.

DRYMATIC II

• Quiet, intelligent & energy-efficient

• Quiet, intelligent & energy-efficient

• Can operate as a Positive, Negative, or Balanced Drying System

• Heat & Air Exchange to optimise drying conditions

• Excels in Class 4 Specialty Drying situations

• Flexible system with a range of attachments

• Stackable rotomoulded double skinned housing/body

• Weight is only 28kgs

• Portable, plugs into a standard 13 Amp Power Outlet (no gas or diesel required)

• Touch-safe heater outlet

• Quick-fix hose connection

• Wheels for easy maneuverability

• Significantly reduces drying life cycles

• Enhance your experience with the 7 Port Adaptor Kit – turn your Drymatic II into a Push/Pull cavity drying system!

Each Drymatic II comes with : 3 x 6m of 150mm Grey Hoses; 1 x 6m of 150mm Foil Hose, 4 x rotomoulded screw in connections; 4 x Jubilee clips; and a hose bag

HOW IT WORKS

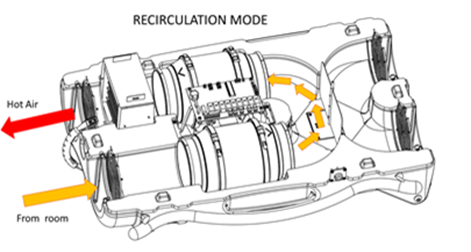

Recirculation Mode

During re-circulation Mode the Drymatic II takes air in through the Room Intake, measuring Temp and %RH, and then reheats the air to help raise the ambient temperature within the drying chamber.

The drying chamber is continuously heated up until either a user-defined Temperature (C/F) or Relative Humidity (%RH) limit is reached, or until the machine determines that the system needs to make a change based on rates of change within the drying environment.

The Drymatic II uses re-circulation mode to maximise temperature gain, whilst minimising heat loss through the Exhaust process.

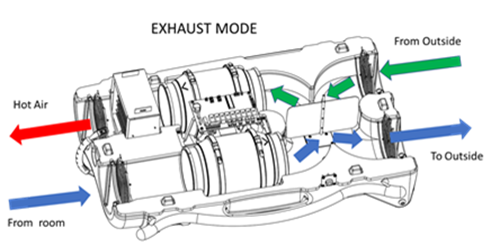

Exhaust Mode

In Exhaust Mode the Drymatic II takes air in from the Room Intake and purges it straight through the machine to outside via the Outside Exhaust - exhausting up to 595m3/hr of air. At the same time the machine takes in replenishment air from an unaffected area (e.g. outside air, air from an unaffected space, or process air from a HVAC system or dehumidifier) and heats that air before pushing it in to the drying chamber.

The Drymatic II can autonomously cycle between the Re-circulation and Exhaust modes to maximize the amount of water removed from the area.

THE ADAPTOR KITS

DRYMATIC II INJECTION DRYING/EXTRACTION ADAPTOR KIT

DRYMATIC II INJECTION DRYING/EXTRACTION ADAPTOR KIT

Further enhance your Drymatic II experience! Turn your Drymatic II into a Push/Pull cavity drying system using our 7-Port adaptors and hose kit. Create Positive, Negative or Balanced drying regimes by manipulating the number of connections fitted.

Included: 2 x Drymatic II Multi-port Adaptors (38mm); 30m of 38mm Hoses; 14 x Hose Cuffs; 1 x Carry Bag

DRYMATIC II Y PIECE ADAPTOR KIT

DRYMATIC II Y PIECE ADAPTOR KIT

The Y-piece splitter allows you to direct your airflow into separate chambers from the Drymatic II. This Y-Piece allows you to duct the controlled heated airflow into 2 areas.

Included: Y Piece Adaptor 3 x 5m 150mm Hose; 3 x Jubilee Clips; 1 x 150mm to 150mm Joiner; 1 x Carry Bag

DRYMATIC II EXHAUST ADAPTOR KIT

DRYMATIC II EXHAUST ADAPTOR KIT

The Exhaust adaptor allows the Drymatic II Outside Exhaust duct to be reduced from 150mm to 100mm which allows you to exhaust your Drymatic II into a smaller aperture, such as a letterbox, kitchen extraction fan, or air-vent.

Included: 1 x 150mm to 100 Reducer Adaptor; 2 x Jubilee Clips ;1 x 6m of 100mm Hose

KITCHEN KIT

The Kitchen Kit gives you the ability to further reduce the size of your hose so that you can gain access to even harder to reach areas. The reducers drop the hose down from 38mm to 25mm and this is perfect for insertion into the base of kitchen cabinetry. Simply pop in a flush-mount vent cover when you are done.

Included: 14 x 38mm to 25mm Step Down Connectors and 2.5m of 25mm Black Hose

DOWNLOAD

Drymatic II-Instruction Manual (PDF)

Drymatic II Floor System Spec Sheet (PDF)

Drymatic II Fact Sheet (PDF)

Drymatic II Environmental Benefits (PDF)

Product Catalog (PDF)